Will Galvanized Garden Beds Rust

Our Ultimate Guide To Weathering Steel

What is Weathering Steel?

In this guide we present some of the most commonly asked questions around weathering steel. Corten is such a versatile material with many mysteries, we answer those questions here, so you can get your building cladded or your garden edging happening as soon as possible.

Attributes of Corten

Weathering Resistance

Thanks to high weather resistance, corten steel can be used without painting. Unpainted applications are not only offer the economic advantage of reducing repainting costs; they also offer aesthetic benefits associated with the calming color of the protective rust.

Paint Durability

COR-TEN is paintable in the same way as ordinary steel. In addition, even if a painting defect should occur, COR-TEN suppresses the progress of rust area and prolongs the services life of paint, thereby reducing repainting costs.

Weldability

While trace amounts of alloying elements such as copper (Cu) and chromate (Cr) are added to COR-TEN to ensure high weather resistance, the carbon content is lowered to provide appropriate weldability. Accordingly, COR-TEN can be welded using either manual, gas-shield or submerged arc welding.

Workability

COR-TEN possesses workability similar to ordinary steels of same strength

Reliability

Since 1959 when COR-TEN began to be marked, more than 4.8 million tons of this material have been produced. (2015 end)

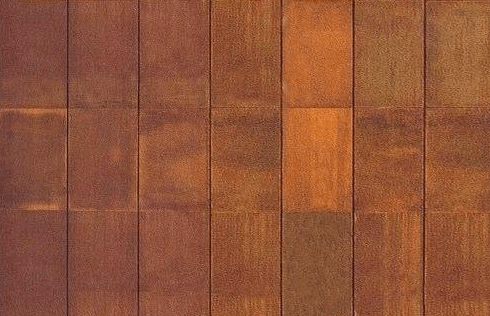

If you've been searching for the perfect rustic look for your metal roof or siding, weathered steel will take your expectations to a new level. Weathered steel is a finish that will be completely unique to every project, every time. You may hear it referred to as a Corten or Truten A606, both of which are just different names used to describe the finish. Weathering steel creates an unbelievable, one-of-a-kind look. As the finish is exposed to different types of weather, it begins to rust into a gorgeous, rustic look over time.

COR-TEN has served as weathering steel (atmospheric corrosion- resistant steel). Corten steel plate has successfully overcome rust, steel's most weakest. When exposed to the atmosphere without painting, corten steel begins to rust in the same way as ordinary steel. BUT soon the alloying elements in COR-TEN cause a protective surface layer of the fine-textured rust to form, thereby suppressing corrosion rate. Since its development in 1993, the COR-TEN has been used in every field where steel applied, such as bridges, railway vehicle and buildings. At present, COR-TEN are attracting attention as being suited for resources and environmental concerns as well as reducing life-cycle costs.

Weathering Steel was originally designed for for rail cars in the 1930's but soon became popular for bridges and other large outside structures for the look and to eliminate the need for painting; instead they had a stable rust layer on the surface, brought on by time in the weather. This was much easier than painting a bridge and having to start again at the other end by the time you were finished!

Corten is created when the metal gets wet and the dries out, the rust layer becomes a little thicker, while the underlying solid steel becomes thinner. In an ideal world, the rust layer would continue to take hold of the steel for two or three years before stabilizing. The result should be a maintenance-free material with a unique aesthetic.

When COR-TEN is painted, the required number of times that repainting must be conducted can be reduced. This advantage is believed to result from the fact that, even when corrosion in the base metal due to defects in the panted film or to pinholes, the corrosion progresses slowly and thus the occurrence of blistering and peeling of the paint film is reduced. By making the most of this advantage. COR-TEN is applied in every field where steel is used-ranging from buildings to railway vehicle, marine containers, storage tanks, industrial machinery and bridges.

Weathering steel, often referred to by the genericized trademark COR-TEN steel, is a group of steel alloys developed to form a stable corrosion-resistant surface after several years exposure to weather, potentially eliminating the need for painting in many environments. U.S. Steel (USS) holds the registered trademark on the name COR-TEN, which refers to the two distinguishing properties of this type of steel: corrosion resistance and tensile strength. The original COR-TEN received the standard designation A242 (COR-TEN A) from ASTM International. Newer ASTM grades are A588 (COR-TEN B) and A606 for thin sheets. All alloys are in common production and use. Weathering refers to the chemical composition of these steels, allowing them to exhibit increased resistance to atmospheric corrosion compared to other steels. This is because the steel forms a protective rust patina on its surface under the influence of the weather. The corrosion-retarding effect of the protective layer is produced by the distribution and concentration of alloying elements in the steel chemistry.

Un-painted Corten Steel

The unpainted application of corten steel not only offer economic advantages but also demonstrates excellent aesthetic properties. Because of this, COR-TEN is applied in a wide range of fields such as buildings and monuments. COR-TEN can be applied without painting-in a bare state, thus reducing the cost of repainting and other repairs. However, some of our clients have expressed their concerns during the first year or two then the protective lay of fine-textured rust is forming. In order to solve these concerns, supplementary rust stabilization treatment was developed.

How Does Weathering Steel Work?

The weathered steel finish begins with a top coat made of copper, phosphorus and silicon. It forms a textured oxide surface film on the panel and as time passes, and the panel is exposed to the different weather elements like rain or snow, it begins rusting into a unique patina-like color.

Weathering steel is extremely resistant to corrosion caused by weather and other atmospheric conditions. Once the coating is gone, the steel ionizes, which makes it so the steel does not continue to rust and you won't have to worry about the panel being rusted all the way through. The base layer of steel will last just as long as other finishes (so you can expect your roof or siding to last between 40 and 70 years).

Weathered steel finishes outperform many carbon steels that display a coarse, flaxy oxide. This finish is becoming more and more popular for homeowners, builders and commercial property owners because each panel rusts into its own one-of-a-kind color and look. Depending on the area and climate you live in, the panels will weather differently. Some may take slightly longer to weather and some could potentially be slightly different colors. That's the beauty of weathering steel—it's completely unique to you!

Can weathering steel be galvanized?

High-strength steels, such as weathering steel, generally exhibit noticeably heavier galvanized coatings than carbon steels. Normally, the thickness of the galvanized coating is appreciably affected by the surface roughness of the steel prior to galvanizing. However, in the case of weathering steel, the coating weights are comparable for both pickled and blast-cleaned surfaces, whereas in carbon steels the blast-cleaned surfaces will normally galvanize with a heavier coating. Therefore, the increased thickness of galvanized coatings on weathering steel is mainly due to higher levels of silicon that are not found in typical carbon steels. The high content of silicon, such as is in ASTM A588 Grade A, is known to promote the growth of iron-zinc alloy layers during hot-dip galvanizing (Grade A has approximately 0.40 Si whereas carbon steel normally has less than 0.02 Si), which ultimately increases the overall coating thickness. The appearance of the galvanized coating on weathering steel also slightly differs from a typical coating on carbon steel. A bright spangle or bright galvanized steel is characterized by a coating that is relatively pure zinc near the surface; conversely, a matte galvanized finish is characterized by a coating that consists of an iron-zinc alloy at the surface. A matte gray coating with little or no spangle should be expected when galvanizing weathering steel.

What objects are suitable for Galvanising?

The process of coating a thicker metal base with zinc shields the material from the elements and prevents corrosion. The steel is protected from rust and erosion that can be caused when the object is exposed to rain, high or low temperatures in the climate and some chemicals that some into contact with it. In simple terms the process of galvanising steel elongates it's life and ensure the metal will be of the highest quality as possible, for as long as possible. Galvanising steel means that the material will remain reliable and strong. Using galvanised steel is also a cost effective alternative to using materials such as aluminium or stainless steel.

How long does Corten steel take to rust?

Corten is a trade name for a steel alloy material originally produced by US Steel. Corten is a weathering steel. The material is corrosion resistant steel and if left uncoated develops an outer layer patina. This patina protects the steel from additional corrosion.

Corten Steel Planters are made to rust and will start showing the signs of rusting if you just put them outside for a couple of weeks and let mother nature take its course.

If you want to initiate the rusting quickly, first wash the planter with warm water and soap. This will remove any remnants of oil and the water will react with the metal initiating oxidation (rusting). Next, mix together the following ingredients into a spray bottle, or a fertilizer pump sprayer:

16oz Hydrogen Peroxide (Use a fresh bottle)

2 oz White Vinegar

1/2 Tablespoon of salt.

By using this mixture and lightly spraying the planter 3-4 times a day, you will achieve the fully rusted look in a matter of a few days.

Does Galvanised steel rust?

Galvanized steel has been used for almost 2,000 years because of its unrivaled ability to last a very long time and resist rust. Hot dipped galvanized steel and electroplated galvanized steel are made using different methods and their zinc galvanized coatings corrode completely differently. Learn about these galvanizing processes (here) and how zinc corrosion varies between them (here).

Yes, galvanized steel resistance to rust corrosion depends largely on the type and thickness of the protective galvanized zinc coating, but the type of corrosive environment is also a critical factor.

Factors that rust and corrode galvanized steel:

Relative humidity above 60%

Sodium chloride (salt) in water or air

Wet or soaked environments

Increase in temperature when combined with corrosive factors like humidity and industrial pollution

Acids; particularly sulfur acids produced by (1) hydrogen sulfide - from volcanoes, hot springs, natural gas, and sewer gas - and (2) sulfur dioxide pollution in the urban atmosphere

Strong Alkalis

Plasters and cements (especially Portland cements) containing chlorides and sulfates

Acid rainwater runoff from roofs with wood shingles

Moss and lichen

Contact between galvanized items and copper, pure iron, or steel causes galvanic corrosion. Galvanic (electrochemical) corrosion is an electrolytic corrosion reaction between the zinc coating and dissimilar metals when in the presence of an electrolyte such as rain, dew, fog or condensation.

Acidic food and drinks

Galvanized steel has good resistance to:

Concrete

Mortar

Lead

Tin

Zinc

Aluminum

Galvanized steel is corrosive to all metals except lead, tin, zinc and aluminum.

Although it does not last infinitely, galvanized steel is the unparalleled corrosion-resistant metal. It is worth noting however, that applying a protective coating such as paint to galvanized steel will alleviate the problems caused by corrosion of the protective zinc coating.

Groundwater carries micro-organisms, eroded soil, decaying vegetation, dissolved salts of calcium, magnesium, iron, and manganese, and suspended colloidal matter. All of these substances and other factors such as pH, temperature, and motion affect the structure and composition of the corrosion products formed on the exposed zinc surface.

Relatively small differences in freshwater content or conditions can produce relatively substantial changes in corrosion products and rate. Thus, there is no simple rule governing the corrosion rate of zinc in fresh water. However, one trend data supports is hard water is much less corrosive than soft water. Under conditions of moderate or high water hardness, a natural scale of insoluble salts tends to form on the galvanized surface. These combine with zinc to form a protective barrier of calcium carbonate and basic zinc carbonate which slow the corrosion rate.

The biggest factors in the zinc corrosion rate in fresh water are dissolved gasses, hardness/mineral rate, flow rate, and other ions/chlorides.

Gasses: More oxygen means more corrosion products on the surface of the zinc which increases the corrosion rate. For this reason, fully immersed in the water is better than partial immersion because there is less oxygen under water. Well waters tend to have a lower content of dissolved oxygen, so corrosion is low, while surface waters and springs have higher rates.

Hardness: In hard water, zinc combines with carbonates and bio carbonates to form zinc carbonate, which unlike zinc oxide, is not water soluble. The zinc carbonate deposits on the surface of the zinc and creates a passive film on the galvanized part slowing corrosion. The softer the water, the lower it is in carbonate; therefore, soft water is more corrosive than hard.

Flow Rate: Higher flow rates tend to increase corrosion because it acts similar to wind in atmospheric exposure it means increased abrasion.

Other Ions: Chloride is the most aggressive ion to zinc, namely when over 50 mg/L. This tends to be more pronounced in soft waters which often have carbonate levels below 80 mg/L, whereas hard waters have 700 mg/L. The protective film deposited by carbonate in hard water protects the zinc coating from anion attack.

Can you weld weathering steel?

Corten is another name for weathering steel. Essentially, it is steel that rusts nicely and develops a beautiful patina that is desirable to many. It contains minimal amounts of Chromium, Nickel, and Copper, which gives it its weather resistance, making it suitable for use on structural applications. If you are interested in learning how to weld Corten steel, then keep on reading. In this article, we'll discuss how to weld Corten steel as well as topics like how to choose the right filler wire.

Weathering steel does not prevent rust. In fact, the material alters the way the rust affects the structure. The presence of chromium, nickel, and copper add to the material weather resistance. It allows for the rust to dry quicker and thicker, developing a beautiful patina.

However, instead of weakening the structure, the rust forms a paint-like layer over the material. The coating protects the un-reacted material from the atmosphere, and it allows the material to retain its load-bearing capacity and thickness for longer.

Many sculptors and architects prefer it for aesthetic reasons. The natural patina that it develops over time adds a rustic charm and character to many structures.

The precautionary requirements for welding Corten are similar to that of welding mild steel. The only significant difference is that you may need a different filler wire than you would typically use. The AWS classified 6013, used for mild steel, is not acceptable for Corten.

The two types of welding procedures that you can effortlessly use are Metal Inert Gas and basic Arc Welding or shielded metal arc welding (SMAW).

What is Grade a588 Steel?

ASTM A588 Grade A and A588 Grade B are highly resistant to atmospheric corrosion, superior corrosion resistance over regular carbon steel as a result of the development of a protective oxide film on the metals surface which slows down further corrosion. Both are high-strength low-alloy weathering steels which exhibits 50,000 minimum yield strength characteristic allows cost reduction through the ability to design lighter sections into structures.

These steels are designed primarily to be used in unpainted applications where a reduction in maintenance costs included such as painting. Since their development, weathering steels have been used in a variety of applications, including bridges, rail cars, crane, transmission towers, highway poles, chemical plant, factory and real health medical shipbuilding.

A588 is suitable for many applications in the unpainted condition. The atmospheric corrosion resistance of A588 is substantially better than that of carbon steels such as A36 and A572-50 with or without copper addition when properly exposed to the atmosphere.

Corten Steel and Your Garden

Over recent years weathering steel has become extremely popular in peoples yards as garden planters and garden edging, the appearance is breathtaking, therefore, corten steel garden products are highly sought after. Corten has grown so much in popularity over the last decade that the term is now used to describe the steel type in general rather than just describing the original brand name.

COR-TEN (or simply Corten) is the trademark name for the steel type also referred to as Weathering Steel. The COR relates to corrosive resistance while the TEN relates to it having high tensile strength.

The recipe of alloys prescribed for Corten steel or Weathering Steel, whichever you choose to call it, is what gives this steel the unique qualities it has.

Using Corten Steel instead of Wood

In the long run, Corten Steel was a better investment than the 'correct' wood you should be using in edible gardens.

Pressure treated wood, the stuff that resists degradation of weathering, is filled with chemicals. It's literally soaked in chemicals (that's its job!). And we don't want that soaking into the soil we're using to grow food. The same goes for those 'fun DIY' gardens where people like to use old railroad ties. Which are soaked in creosote. Which you also don't want in your soil.

Pressure treated wood has its place. That's why we used it to build a fence and retaining wall for our non edible garden. With that said, we also took time to line the back of the retaining wall so the soil wouldn't directly come in contact with the dirt.

The bottom line being, the only wood you should really be using that would last a long time for an edible garden is cedar. That shit is EXPENSIVE. And eventually you do have to replace it. We ended up calculating it out that really buying Corten Steel beds would mean spending less in the long run.

You never need to paint or seal Corten since a stable rust-like look is naturally formed after several years, completely resists corrosion. (the problem with using metal outside) and you never need to worry about rain, snow, humidity etc. It's completely resistant to frost and cracking that can happen in colder climates.

But after all that practicality…they look amazing. Chris and I describe our backyard as 'controlled lush'. We like a ton of plants that combine and overlap and grow like crazy, but we also want modern, clean lines. Corten steel is the perfect linear, modern balance to other choices made in the yard.

Does Weathering Steel Look Ugly During The Oxidation Process?

You might fall in love with the look of the product right out of the box. It's a pretty warm metal look. I mean, I liked it! But it does get 'better' looking with time and if you look at photos on Pinterest of well developed gardens, you'll typically find these planters. They don't stand out and scream ORANGE, just modern natural vibes. They're used at a ton of architecturally driven locations.

It takes different amounts of time in different climates but in general the more wet to dry moments that happen, the faster it tends to go.

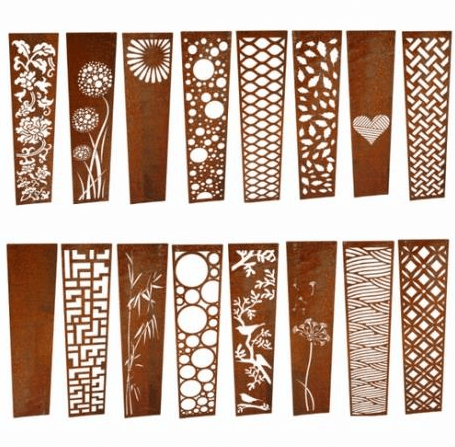

But Steel Usually Just Rusts Away in My Garden, Like Steel Ornaments, Why is Weathering Steel Different?

Steel garden ornaments are often made with a thin gauge mild steel because it's easy to cut and can therefore have more intricate detailing. Simply put, that steel isn't designed for existing outside in the elements and as it begins to rust, it can rust away quite quickly. The question you can ask when buying such ornaments is whether it's made of weathering steel and if it's not, then look at the thickness of the actual steel used. 3-5mm mild steel will also last a fairly long time in any garden, irrespective of the conditions.

As for why the weathering steel used as a garden edge lasts longer, the simple difference is weathering steel is designed to gain strength from being exposed to the atmosphere. As a minimum your looking at it being structurally sound for at least 10 years.

Is Corten Steel Safe to Grow Vegetables?

This question is answered well in the Kitchen Garden Revival book,

"Although steel is made from mined iron, it's been proven to be quite a sustainable resource, as it can always be completely recycled. Some steel may be treated with zinc for durability but there's little to no chance this will affect the organic nature of your soil.

Steel gardens will, literally, last a lifetime—and then some. And one thing I love about garden beds made with steel is the small footprint of the bed itself. If you're growing in a small space and want to maximize your growing area, a steel bed enables you to give nearly all the space to your plants while still having a super strong garden bed that will never give up growing."

Does Corten Steel Stain Concrete?

Home Preservation Manual Says

Home preservations article on Corten reads as follows-

Cor-ten steel is a type of metal used for exterior applications where a weathered and rusty appearance is desired. This material has rustic, industrial-contemporary good-looks, but is not for every application.

Generically known as "weathering steel" this product is a family of steel alloys developed specifically to form a stable, rust-like surface appearance that eliminates the need for painting. Cor-ten is US Steel's trademark name for its weathering steel formula.

The alloys in weathering steel allow rust or surface oxidation to occur naturally over the course of about six months under normal exterior conditions. Use of chemical treatments can help speed up the process and produce the patina in as little as two hours. As the steel surface "rusts" it creates a regenerating corrosion-retarding layer that protects the main structure of the steel.

Cor-ten steel has become wildly popular for outdoor sculptures and architectural facades. The look is so attractive that architects have designed entire buildings using the material and it has a legion of residential fans, including me, around the world. This material appears unfinished and rustic at first glance, and that is what makes it so attractive.

Attractive as it is, weathering steel is not perfect for all applications. Its use should be carefully thought through before construction. Cor-ten can be challenging and even damaging to surrounding areas if used improperly. Rust bleeding or runoff from the steel surface can stain surrounding paint, stucco, stone or concrete. Avoid using this material where staining can be a problem. Also, this material is sensitive to humid climates and it is possible that in these areas the protective patina may not form properly, thus allowing the steel to continue to corrode.

Attempts to paint weathering steel have been unsuccessful because paint retards the protective patina from forming properly. When this happens, deep corrosion can occur at localized areas of oxidation like under small paint cracks or chips.

Will Galvanized Garden Beds Rust

Source: https://www.metfab.com.au/corten-steel/

Posted by: nishimuranaturawrove.blogspot.com

0 Response to "Will Galvanized Garden Beds Rust"

Post a Comment